Product Category

Contact Us

Email:

Marketing Team:

Peter:

Mob / whatsapp / wechat: +86-13901526328

Maya:

Mob / whatsapp / wechat: +86-19941583627

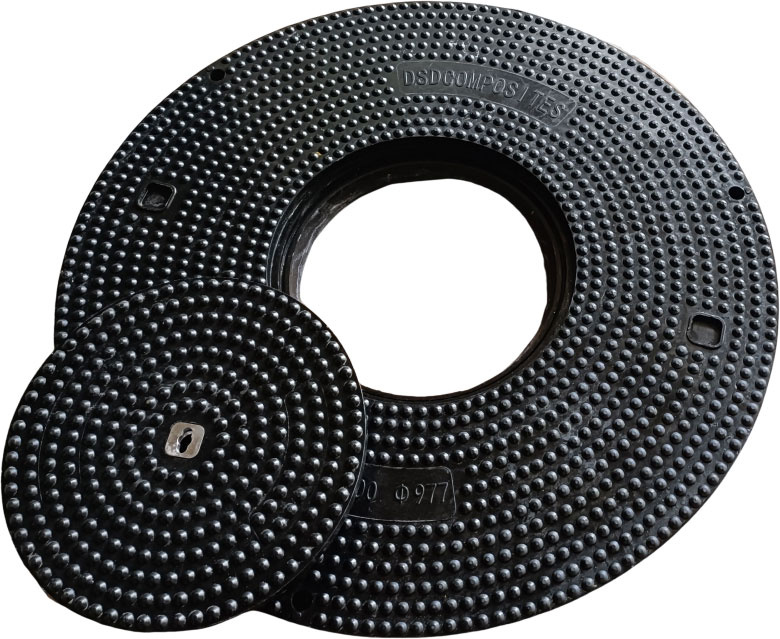

Φ900mm D400 Petrol Station Heavy Duty SMC Composite Manhole Cover

1.This series of products can achieve a bearing capacity higher than the standard EN124 D400. DSD manhole cover has high-quality sheet materials produced by advanced sheet equipment, industry-leading lightweight design and large press production of 1500 tons.

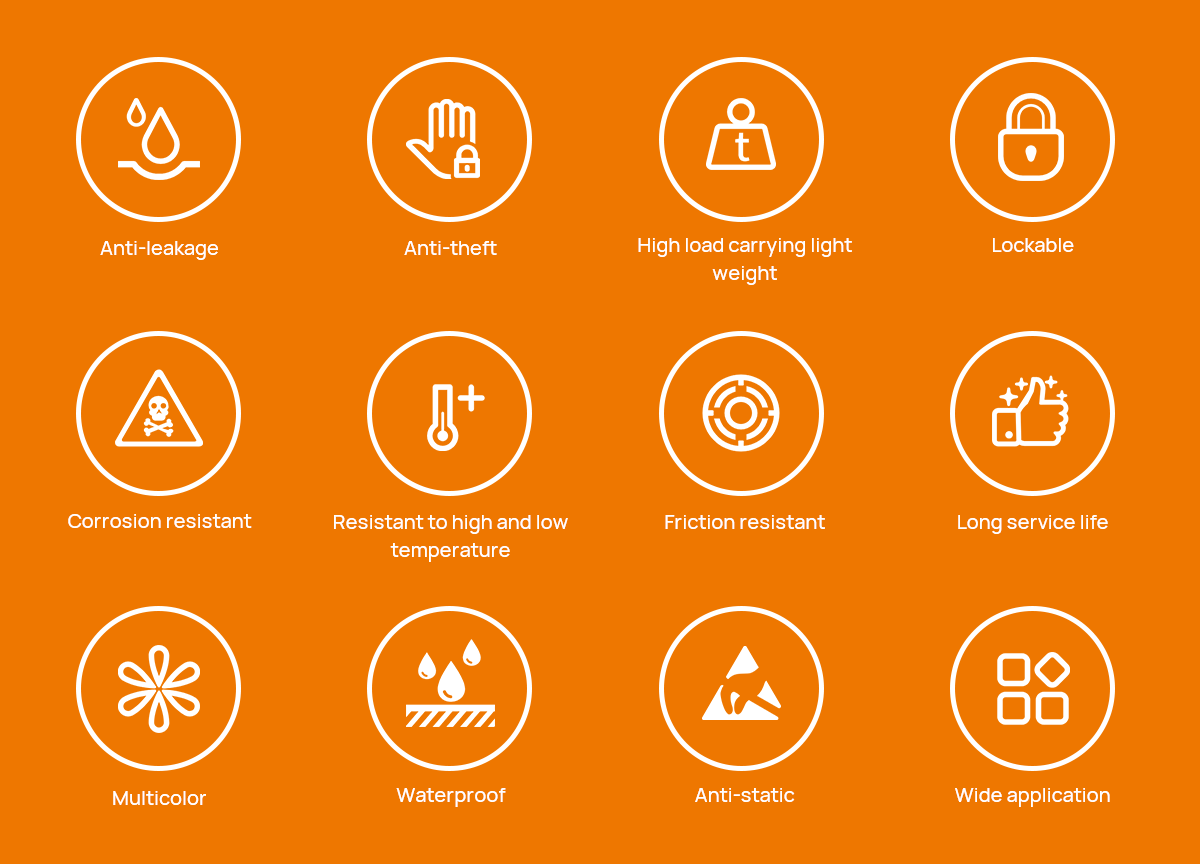

2.The products have high density, strong resistance to pressure, bending resistance, impact resistance, heat and cold resistance, abrasion and aging resistance, acid and alkali corrosion resistance and not easy deformation.

3.It utilizes special material for the sealing ring design, with leak proof function, including to prevent the rainwater seep into, sewage overflow and smell out. It’s able to solve the noise generated by passing vehicles to prevent noise pollution and environmental pollution.

Classification:

- Product Details

-

Petrol station/ leak proof manhole covers

1. This series of products can achieve a bearing capacity higher than the standard EN124 D400. DSD manhole cover has high-quality sheet materials produced by advanced sheet equipment, industry-leading lightweight design and large press production of 1500 tons.

2. The products have high density, strong resistance to pressure, bending resistance, impact resistance, heat and cold resistance, abrasion and aging resistance, acid and alkali corrosion resistance and not easy deformation.

3. It utilizes special material for the sealing ring design, with leak proof function, including to prevent the rainwater seep into, sewage overflow and smell out. It’s able to solve the noise generated by passing vehicles to prevent noise pollution and environmental pollution.

Product information

Name

Fuel Station Cover With Inspection Hole

Material:

FRP Composite (SMC)

Features:

With central port cover

Clear opening:

900mm

Weight:

85.4kgs

Load:

D400、C250

Standard:

EN124-5

Work Temp.

-50°C ~ +150°C

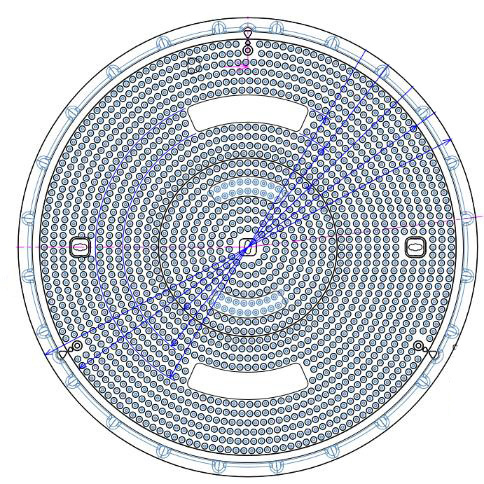

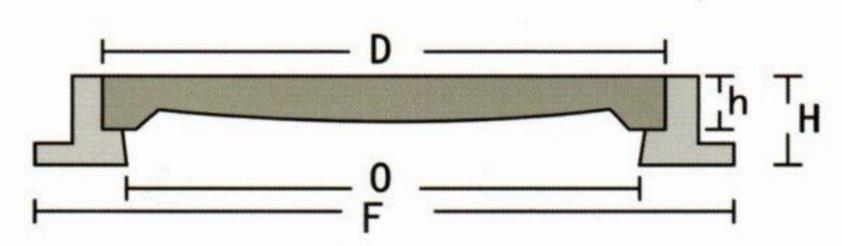

Specification

Product Code

Load

Clear Open

DiaManhole Cover

DiaManhole Frame

ODManhole Cover

DepthManhole Frame

HeightWeight

Function

O

D

F

h

H

DSD-ZX900H

D400

900

976

1078

50

100

85.4KG

Center inspection cover

Unit: mm

Diameter is 900 mm, loading class is EN124 D400, designed for fuel station with double sealing including a sealed central cover on the main cover.Features

Anti-Slip surface

DSD Manhole Cover's top surface material boasts superior slip-resistance in wet, dry or worn conditions for increased safety.

Watertight Seal

Integral covers create an airtight seal between their frame and cover to maintain watertight performance.

With Central Inspection Port Cover

There is a locking sealing inspection port cover with an opening of 350mm (13.8") at the centre of this manhole cover for waterproof inspection purposes, providing access for inspection.

Material

Frame and inspection cover are constructed of SMC FRP composite material. Removable side sealing structure utilizes corrosion-resistant EPDM rubber while removable sealing handle adopts aluminum alloy. Three M10x40 hexagon socket head locking screws made from 304 stainless steel are utilized, as is its locking mechanism comprising aluminum alloy and 304 stainless steel components.

Lockable

Lockable access covers can not only increase site and location security but can also protect against theft and malicious damage.

Customized LOGO available

DSD Manhole Cover has an experienced engineering department which allows them to make custom designed moulds according to customer size, pattern, color, load limit load logo function requirements.Advantage

Application

Production

Packing

Transport

1.Standard plywood case, its compressive strength and bearing quality is better

2.The board area is bit, the soil structure is good, it is better in leakproofness and waterproof

3.When importing, the plywood case is with fumigation-free, the procedure is simple.

4.Delivery Detail: within 7-15 days after received your payment

Q & A

Q

What is SMC materials?

A

SMC composite is a short form of “Sheet Molding Compound”. It’s composed of resin, fiberglass and other chemical polymers, it’s homogeneous material and often used in aerospace composite structures.

The outstanding advantages of SMC composites:

- It can maintain good dielectric performance under high frequency, and does not reflect or block the microwave. It is suitable for application in crowded or narrow places, and can effectively avoid the danger of electric shock.

- It has effective resistance to water, gasoline, alcohol, electrolyte salt, acetic acid, sodium potassium compounds, asphalt, acid base soil and acid rain corrosion.

- Under the combined action of three-dimensional network molecular structure and reinforcing fiber, the material has good impact resistance, easy to be machined, easy to drill and cut, and accurate positioning.

- It has strong impact resistance to avoid deformation, with high tensile strength, bending strength and impact toughness.

- As a smokeless and non-toxic materials, it does not contain halogens, and it’s an environmentally friendly material that can meet the needs of future development.

- The fire retardant can reach to FV0 level, and the smoke & gas level is quasi-safety level 1 (ZA1), which meets the requirements of domestic and international UL94 standards.

- It’s poor conductor of heat, has low deformation rate of high-temperature resistance which can reduce the influence of environmental temperature difference on the internal structure of products.

- It’s able to adapt to any kind of harsh weathers, it can be used in the climate of -50°C - +160°C for a long time. The protection level is IP54, which can maintain good physical and mechanical properties.

Key words:

Gas station heavy duty manhole cover

Product Consulting

ENG

ENG