Product Category

Contact Us

Email:

Marketing Team:

Peter:

Mob / whatsapp / wechat: +86-13901526328

Maya:

Mob / whatsapp / wechat: +86-19941583627

Square-SMC

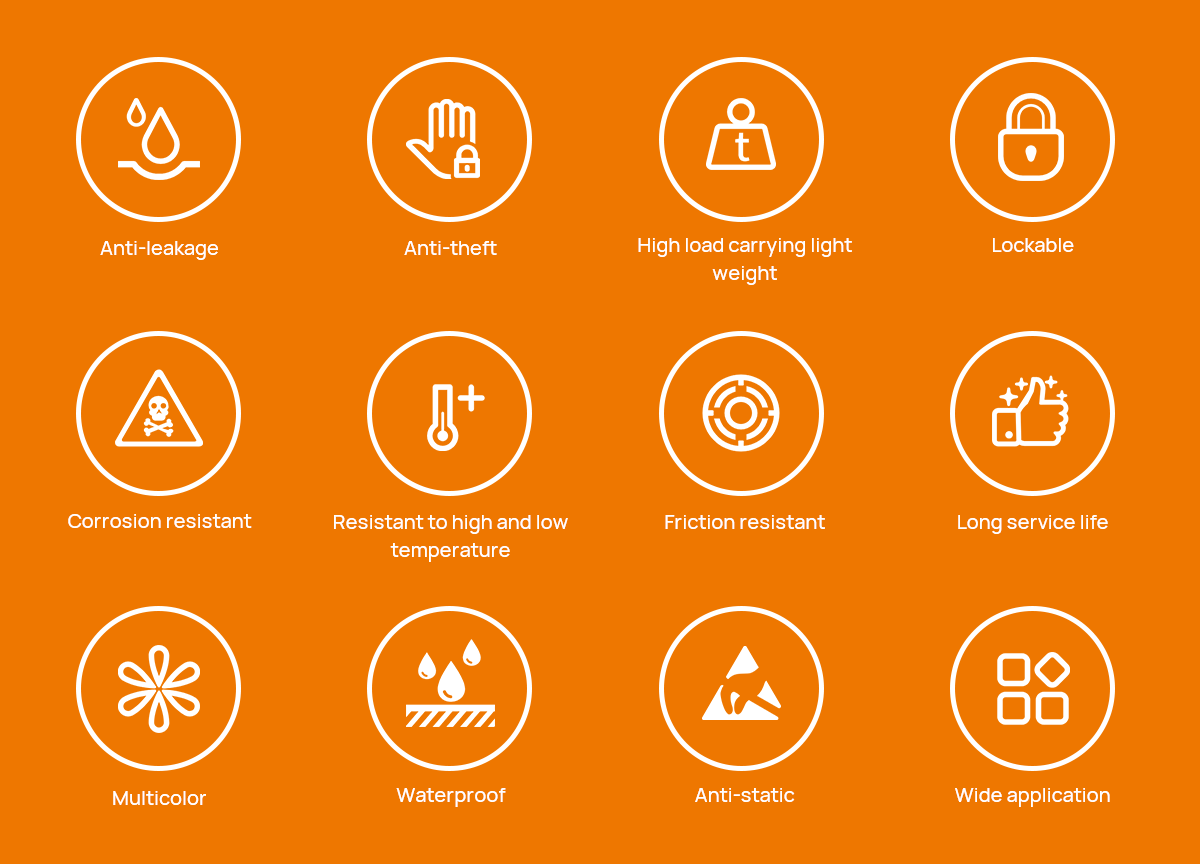

1.This series of products can achieve a bearing capacity higher than the standard EN124 D400. DSD manhole cover has high-quality sheet materials produced by advanced sheet equipment, industry-leading lightweight design and large press production of 1500 tons.

2.The products have high density, strong resistance to pressure, bending resistance, impact resistance, heat and cold resistance, abrasion and aging resistance, acid and alkali corrosion resistance and not easy deformation.

3.It utilizes special material for the sealing ring design, with leak proof function, including to prevent the rainwater seep into, sewage overflow and smell out. It’s able to solve the noise generated by passing vehicles to prevent noise pollution and environmental pollution.

Classification:

- Product Details

-

What are the common models of SMC square fiberglass composite resin manhole covers:

300 * 300mm

400 * 400mm

500 * 500mm

600 * 600mm

450 * 750mm

650 * 850mm

700 * 700mm

860 * 940mm

1000 * 1000mm

1000 * 1500mmMost manufacturers produce square composite resin manhole covers of 1000 * 1000mm and 1000 * 1500mm, which are light and ordinary load-bearing. Large square heavy-duty manhole covers have strict requirements in terms of raw material selection, production process, and inspection process. Only professional manufacturers of SMC national standard composite resin manhole covers can provide heavy-duty national standard manhole covers with quality assurance. The high-quality composite square resin manhole cover is made of SMC glass fiber reinforced composite material, which has high strength, good corrosion resistance, and long service life. It is suitable for areas where cars or heavy trucks frequently appear.

Product information

Product Code

Load

Clear Open

DiaManhole Cover

DiaManhole Frame

ODManhole Cover

DepthManhole Frame

HeightFunction

O

D

F

h

H

W

A15

200x220

244x244

300x300

20

30

sealing

DSD-300X300A

A15

273x273

300x300

355x355

20

30

sealing

DSD-F400X400

A15

375x375

375x375

450x450

20

31

sealing

DSD-500X500A

A15

475x475

500x500

557x557

20

31

sealing

DSD-CO600X450A

A15

600X450

622X472

677X527

20

30

sealing

DSD-600X600

D400 / C250 / B125 / A15

550X550

600X600

690X690

70

100

lockable / sealing

DSD-CO600X600

D400 / C250 / B125 / A15

600X600

660X660

750X750

75

100

lockable / sealing

DSD-CO600X900

D400 / C250 / B125 / A15

600X900

660X960

760X1060

65

100

lockable / sealing

DSD-CO900X900

D400 / C250 / B125 / A15

900X900

960X960

1060X1060

75

110

lockable / sealing

Features

Anti-Slip surface

DSD Manhole Cover’s top surface material has a better slip-resistance value in a wet, dry or worn state to increase safety.

Watertight Seal

Integrated cover creates a watertight seal between the cover and frame.

With Central Inspection Port Cover

There is a locking sealing inspection port cover with a net opening of ∅ 350mm(13.8") in the middle of the manhole cover, which is waterproofMaterial

frame and inspection cover are made of SMC FRP composite material. The removable side sealing structure adopts corrosion-resistant EPDM rubber, the aluminum sleeve of removable sealing handle adopts aluminum alloy, three m10x40 hexagon socket head locking screws adopt 304 stainless steel, and the locking mechanism of inspection cover adopts aluminum alloy and 304 stainless steel

Lockable

Lockable access covers not only improves site and location security and provides security against theft and malicious damage.

Customized LOGO available

DSD manhole cover have professional engineering department and we can make the special design and mould according customer’s size, pattern, color, load, logo, function requirements.

Advantage

Production

Packing

Transport

1.Standard plywood case, its compressive strength and bearing quality is better

2.The board area is bit, the soil structure is good, it is better in leakproofness and waterproof

3.When importing, the plywood case is with fumigation-free, the procedure is simple.

4.Delivery Detail: within 7-15 days after received your payment

Q & A

Q

What is SMC materials?

A

SMC composite is a short form of “Sheet Molding Compound”. It’s composed of resin, fiberglass and other chemical polymers, it’s homogeneous material and often used in aerospace composite structures.

The outstanding advantages of SMC composites:

- It can maintain good dielectric performance under high frequency, and does not reflect or block the microwave. It is suitable for application in crowded or narrow places, and can effectively avoid the danger of electric shock.

- It has effective resistance to water, gasoline, alcohol, electrolyte salt, acetic acid, sodium potassium compounds, asphalt, acid base soil and acid rain corrosion.

- Under the combined action of three-dimensional network molecular structure and reinforcing fiber, the material has good impact resistance, easy to be machined, easy to drill and cut, and accurate positioning.

- It has strong impact resistance to avoid deformation, with high tensile strength, bending strength and impact toughness.

- As a smokeless and non-toxic materials, it does not contain halogens, and it’s an environmentally friendly material that can meet the needs of future development.

- The fire retardant can reach to FV0 level, and the smoke & gas level is quasi-safety level 1 (ZA1), which meets the requirements of domestic and international UL94 standards.

- It’s poor conductor of heat, has low deformation rate of high-temperature resistance which can reduce the influence of environmental temperature difference on the internal structure of products.

- It’s able to adapt to any kind of harsh weathers, it can be used in the climate of -50°C - +160°C for a long time. The protection level is IP54, which can maintain good physical and mechanical properties.

Key words:

Square Manhole Cover

Product Consulting

ENG

ENG