Product Category

Contact Us

Email:

Marketing Team:

Peter:

Mob / whatsapp / wechat: +86-13901526328

Maya:

Mob / whatsapp / wechat: +86-19941583627

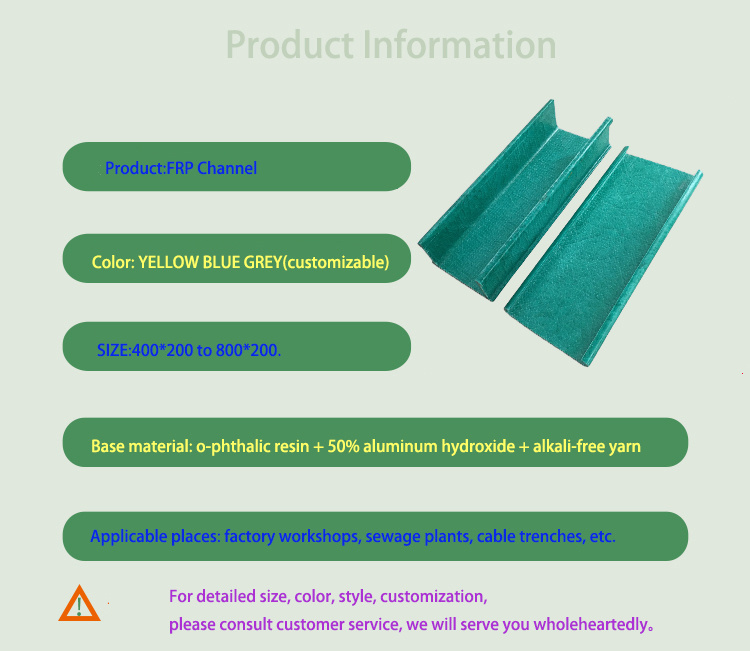

FRP Cable Tray

Classification:

- Product Details

-

FRP CABLE TRAYS PROVIDES BEST SOLUTION FOR HARSH CONDITIONS

When designing a cable management system for your new or existing facility, consider using a fiberglass (FRP/GRP) cable trays over traditional materials. Non-metallic cable trays provide superior protection in harsh environments where corrosion resistance and long life span are important factors.

There are many who still believe that steel outweighs the competition, which is true in that steel does, quite literally, outweigh fiberglass. However, fiberglass provides the same strength-to-weight ratio at just one-third the weight of steel. This allows for an easier, more cost-effective installation. In addition, this weight savings provides tremendous life cycle cost savings. In addition to being resistant to corrosion, the fiberglass cable trays is also non-conductive and non-magnetic, therefore reducing shock hazards.

Feature:

*Corrosion-resistant

* High strength

* High durability

* Lightweight

* Fire retardant

* Easy installation

* Non-conductive

* Non-magnetic

* Does not rust

* Reduce shock hazards

* High performance in marine/coastal environments

* Available in multiple resin options & colors

* No special tools or hot-work permit required for installation

Application:

* Industrial

* Marine

* Mining

* Chemical

* Oil & Gas

* EMI / RFI Testing

* Pollution Control

* Power Plants

* Pulp & Paper

* Offshore

* Recreation

* Building Construction

* Metal Finishing

* Water / Wastewater

* Transportation

* Plating

* Electrical

* Radar

Q & A

Q

What is SMC materials?

A

SMC composite is a short form of “Sheet Molding Compound”. It’s composed of resin, fiberglass and other chemical polymers, it’s homogeneous material and often used in aerospace composite structures.

The outstanding advantages of SMC composites:

- It can maintain good dielectric performance under high frequency, and does not reflect or block the microwave. It is suitable for application in crowded or narrow places, and can effectively avoid the danger of electric shock.

- It has effective resistance to water, gasoline, alcohol, electrolyte salt, acetic acid, sodium potassium compounds, asphalt, acid base soil and acid rain corrosion.

- Under the combined action of three-dimensional network molecular structure and reinforcing fiber, the material has good impact resistance, easy to be machined, easy to drill and cut, and accurate positioning.

- It has strong impact resistance to avoid deformation, with high tensile strength, bending strength and impact toughness.

- As a smokeless and non-toxic materials, it does not contain halogens, and it’s an environmentally friendly material that can meet the needs of future development.

- The fire retardant can reach to FV0 level, and the smoke & gas level is quasi-safety level 1 (ZA1), which meets the requirements of domestic and international UL94 standards.

- It’s poor conductor of heat, has low deformation rate of high-temperature resistance which can reduce the influence of environmental temperature difference on the internal structure of products.

- It’s able to adapt to any kind of harsh weathers, it can be used in the climate of -50°C - +160°C for a long time. The protection level is IP54, which can maintain good physical and mechanical properties.

Key words:

Fiberglass Reinforced Plastic(FRP) Products

Product Consulting

ENG

ENG