Product Category

Contact Us

Email:

Marketing Team:

Peter:

Mob / whatsapp / wechat: +86-13901526328

Maya:

Mob / whatsapp / wechat: +86-19941583627

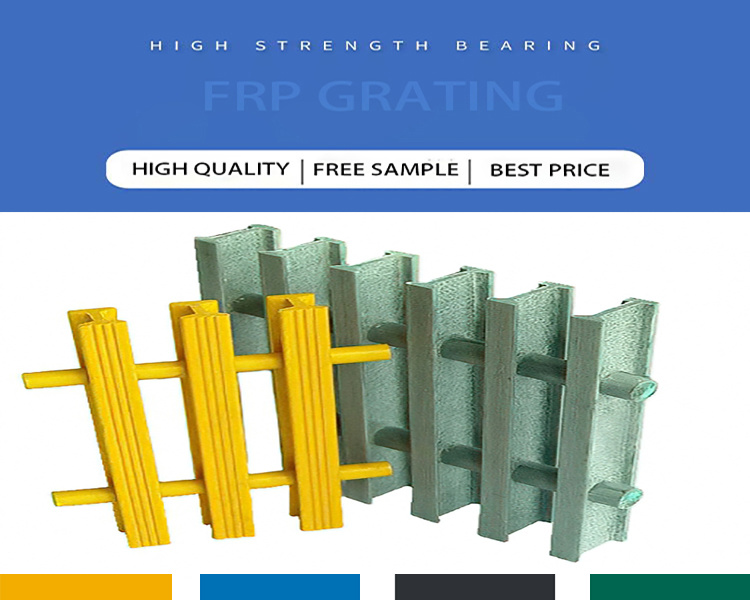

GRP Pultruded Products

Classification:

- Product Details

-

Phenolic Grating is an alternative to maintenance-intensive metallic grating for applications where con- ventional pultruded grating cannot be used.

Our Phenolic Grating has the best combination of flame resistance and low smoke/toxic emissions in industrial pultruded GRP grating. It is able to withstand extended direct contact with flames without burning or incurring structural damage, providing a safe pathway for exit. This feature makes the grating deal for offshore platforms, work boats, marine vessels, access and wellhead platforms, walkways refineries and petroleum processing.

Chemicals

Result

Conclusion

Appearance

Strength retention%

36% Acetic Acid

132

OK

Acetic Acid

92

20% Chloride Acid

96

30% Sulfur

89

80% Sulfur Acid

96

85% Phosphoric Acid

97

85% Formic Acid

No change found

82

15% Silicofluoride Acid

on the surface

85

Benzene

100

Carbon Tetrachloride

99

Saturated Sodium Chloride Solution

91

Ethyl Acetate

75

Dichloroethane

95

Drichloroethane

93

Acetone

Fail

10% Sodium Hydroxide

Exposed glass fibre

10% Nitric Acid

found on the surface

5% Hydrofluoric Acid

Please note

The data above is up to the level of our current knowlege and experience. It is however the responsibilty of the buyer to test our products with respect to their suitability for the specific intended use. No liability is consequently considered as being agreed upon for the data given in this sheet.

Available Resin Types:

• Extremely durable

• Impact resistant

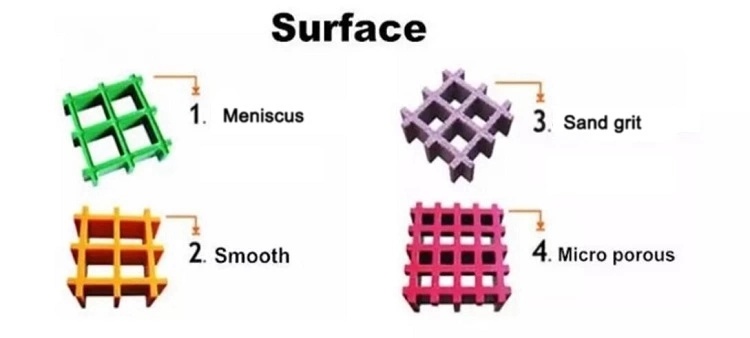

• Anti slip surface

• High flame resistance

• High corrosion resistance

• Low smoke and toxic fume emissions

• High strength-to-weight ratio

• Low maintenance

• High temperature resistance

• Higher service temperature

Q & A

Q

What is SMC materials?

A

SMC composite is a short form of “Sheet Molding Compound”. It’s composed of resin, fiberglass and other chemical polymers, it’s homogeneous material and often used in aerospace composite structures.

The outstanding advantages of SMC composites:

- It can maintain good dielectric performance under high frequency, and does not reflect or block the microwave. It is suitable for application in crowded or narrow places, and can effectively avoid the danger of electric shock.

- It has effective resistance to water, gasoline, alcohol, electrolyte salt, acetic acid, sodium potassium compounds, asphalt, acid base soil and acid rain corrosion.

- Under the combined action of three-dimensional network molecular structure and reinforcing fiber, the material has good impact resistance, easy to be machined, easy to drill and cut, and accurate positioning.

- It has strong impact resistance to avoid deformation, with high tensile strength, bending strength and impact toughness.

- As a smokeless and non-toxic materials, it does not contain halogens, and it’s an environmentally friendly material that can meet the needs of future development.

- The fire retardant can reach to FV0 level, and the smoke & gas level is quasi-safety level 1 (ZA1), which meets the requirements of domestic and international UL94 standards.

- It’s poor conductor of heat, has low deformation rate of high-temperature resistance which can reduce the influence of environmental temperature difference on the internal structure of products.

- It’s able to adapt to any kind of harsh weathers, it can be used in the climate of -50°C - +160°C for a long time. The protection level is IP54, which can maintain good physical and mechanical properties.

Key words:

Fiberglass Reinforced Plastic(FRP) Products

Product Consulting

ENG

ENG